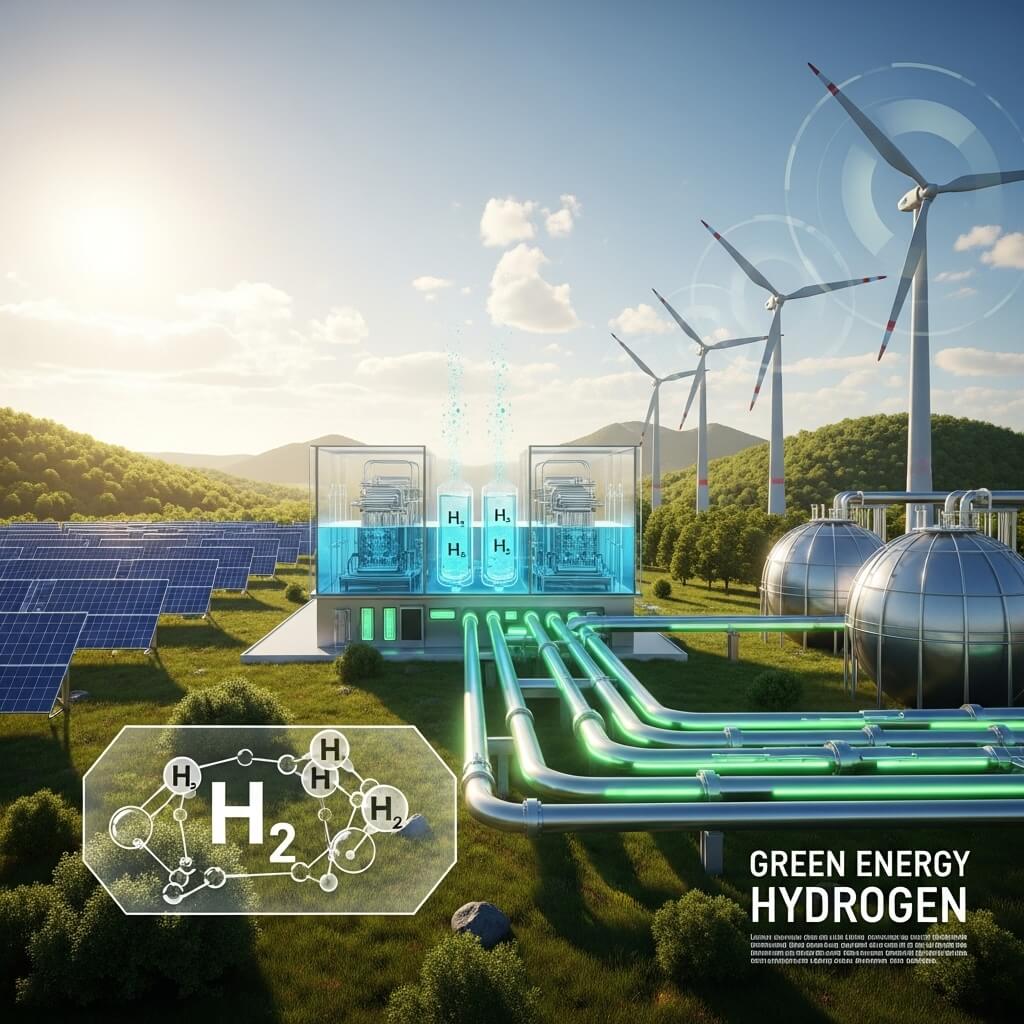

Now, more than ever, it has become urgent to rethink how we use our resources. The energy transition — with hydrogen, fuel cells, and other new technologies — all rely to a certain extent on precious metals as a critical component.

Aimgreen brings a unique process and vision to these markets, enabling the reuse of precious metals from fuel stacks, bipolar plates, and PEM anodes. With demand growing every day, closing this loop has never been more important.

These industries require seperate explanation and market approach

Pt, Pd, Au, Ag, Rh

Aimgreen’s unique non-destructive, non-chemical process allows you to reuse your substrates repeatedly, while we recover the spent precious metal coatings, including PGMs. We supply them back in the form and composition you prefer, helping you further develop your products and contribute to a more competitive, sustainable, and energy-efficient world. Because there is no better moment than now.

Design with purpose means thinking beyond today—considering the end-of-life of every product. In the energy and hydrogen market, we hold the power to reshape global consumption and unlock a new future. Aimgreen isn’t just a contributor, we’re a companion on this journey of transformation.

Our chemical-free process makes it possible to recover the used precious metal layer while reusing the cleaned substrates, greatly reducing the need for expensive replacements.

The outcome is lower operating costs, optimized total cost of ownership, and longer equipment lifespan.

…while reducing your environmental impact.

With real-time tracking, complete documentation, and verified PGM content analysis, Aimgreen gives you clear and transparent insight into the value and results of every batch — making planning, reporting, and scaling simpler than ever.

Sustainability at its core; spent precious metal coatings are converted into high-purity compounds and returned to you for reuse in your coating applications, allowing you to offer more competitive pricing to your customers and amplify your sustainability impact together.

Our recovery process produces highly concentrated, low-volume residues, lowering refining costs. After refining, the metals can be converted into chlorides or sponges and returned to you, reducing reliance on raw materials and cutting overall expenses.

Prolong the lifespan of your anodes with our non-destructive coating removal process. We recover the used layer, prepare the surface, and refurbish the anode, making it ready for immediate reuse.

Extend the life of your anodes with our non-chemical, non-destructive coating removal process. We recover the spent layer, refurbish the surface, and prepare the anode for immediate reuse—reducing costs and enabling you to invest in other areas of your business.

A closed-loop approach is essential for sustainable, efficient, and cost-effective operations. By constantly recycling and reusing materials, you cut waste, reduce emissions, and rely less on newly mined resources. This supports compliance with environmental regulations while helping your business achieve its sustainability goals.

True circularity means restoring a product to its original form — that’s the core of a genuine closed-loop system. At Aimgreen, we’ve built exactly that: a complete solution for full-circle precious metal recovery and supply.

Aimgreen collaborates with long-term logistics partners worldwide ensuring secure and reliable shipments.

We process a wide range of materials containing precious metals (PGMs) in various forms and sizes. Our expertise focuses on iridium and ruthenium-coated materials which we treat using our exclusive, chemical-free method.

Yes, Aimgreen adheres to European environmental regulations. Our innovative, chemical-free recovery techniques meet the highest standards for sustainability safety and environmental protection. We continuously refine and improve our processes.

Any material containing precious metals can be recovered even at very low concentrations. Whether it is coated materials solids liquids hazardous substances organics or catalysts of any form or size our team is ready to assist. Contact us to learn more.

Destructive removal damages both the coating and the underlying substrate rendering it unusable. Non-destructive removal separates the coating while preserving the substrate so it can be reused. At Aimgreen we specialize in a non-destructive chemical-free approach to recover precious metals sustainably.

At Aimgreen, we believe real progress comes from working together. Strong collaboration takes you further than going it alone, and only by combining efforts can we achieve lasting success in circularity.